And out, and in, and out and in (you get the picture).

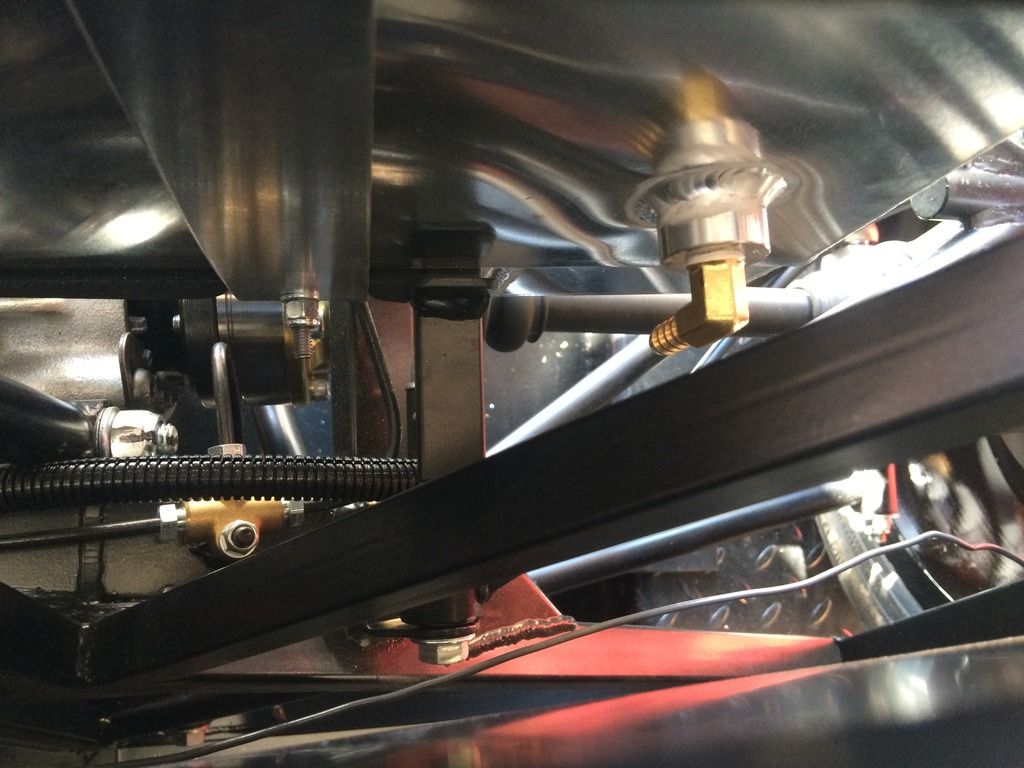

I am mounting the seats on runners so I can accommodate different-sized drivers at the track (i.e. Max and Alex are way taller than me). Mounted the frames on the runners and the runners to the car only to find that there wasn't room to then attach the seat - the seat has to go on to the frame first. Then I found that for the driver's seat the seat bolts foul on the side of the chassis (the left hand side is slightly narrower than the right hand side, as the car was initially designed to be a RHD car, giving slightly more room to the driver than the passenger) so out it came - I tried moving the runners over, but then the seat fouled on the other side - eventually I decided to elongate the holes in the floor (and cut down the seat mounting bolts) to give maximum clearance and now the seat goes forwards as much as I need it). However, I still think the steering wheel is too far away though - will fix that when I add the quick-release boss - by adding a sleeve and an additional piece of rod for the column.

With all the in-and-out of the seats, I finally decided to weld the mounting bolts to the runners - makes it much easier to drop the seats in than trying to locate the bolts on top and the nuts below (it also means it will be easy to remove the passenger seat at the track to save weight, and to avoid taking on unwanted passengers). That means the seats had to come out again. Of course, I didn't have all the nuts and bolts, so there was a trip to the hardware store in there also - couldn't be bothered to wait for another delivery from Westfield.

|

a quick spot welt to each mounting bolt -

just an excuse to play with the welder! |

So, the seats are in!

|

| Seats in and half cage test fitted |

Half cage on to test fit - the bolts that attach the lower stays aren't long enough, so will need those from the factory before I can install it - those I will wait for!

The DHL delivery man just came with a nice fresh bulkhead to replace the dented one, so the seats will have to come out again (easy now I have welded the mounting bolts) and I can finally get around to putting the body on. As this is the biggest and probably most difficult part of the build, I am really looking forward to it. Can't you tell?

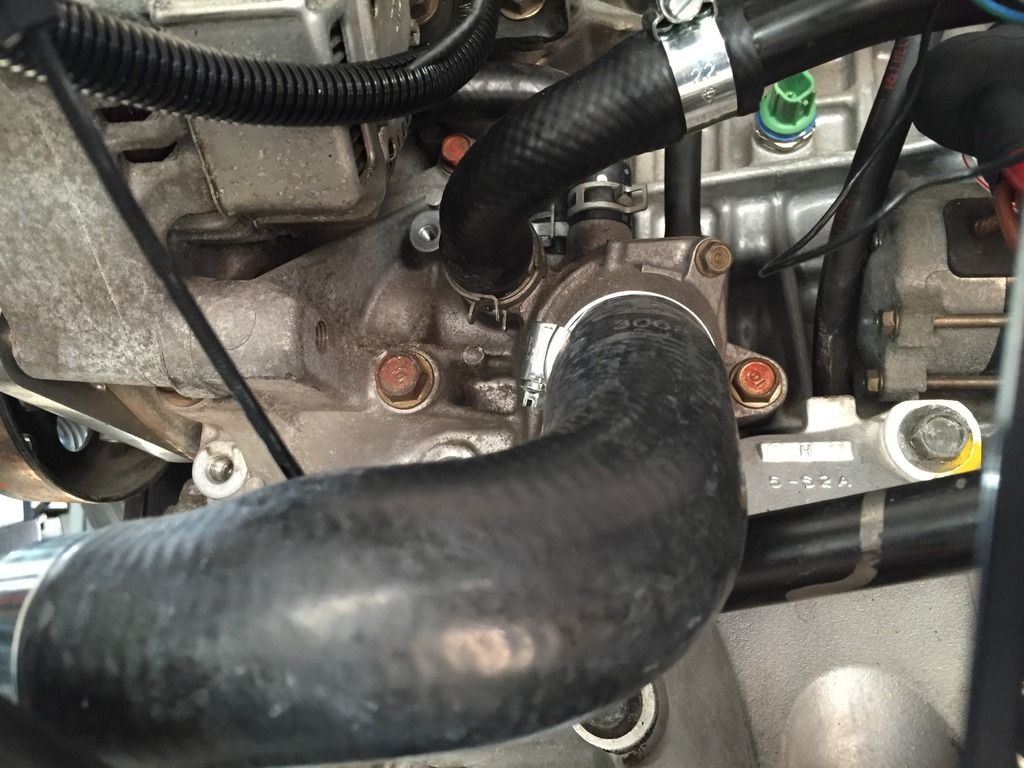

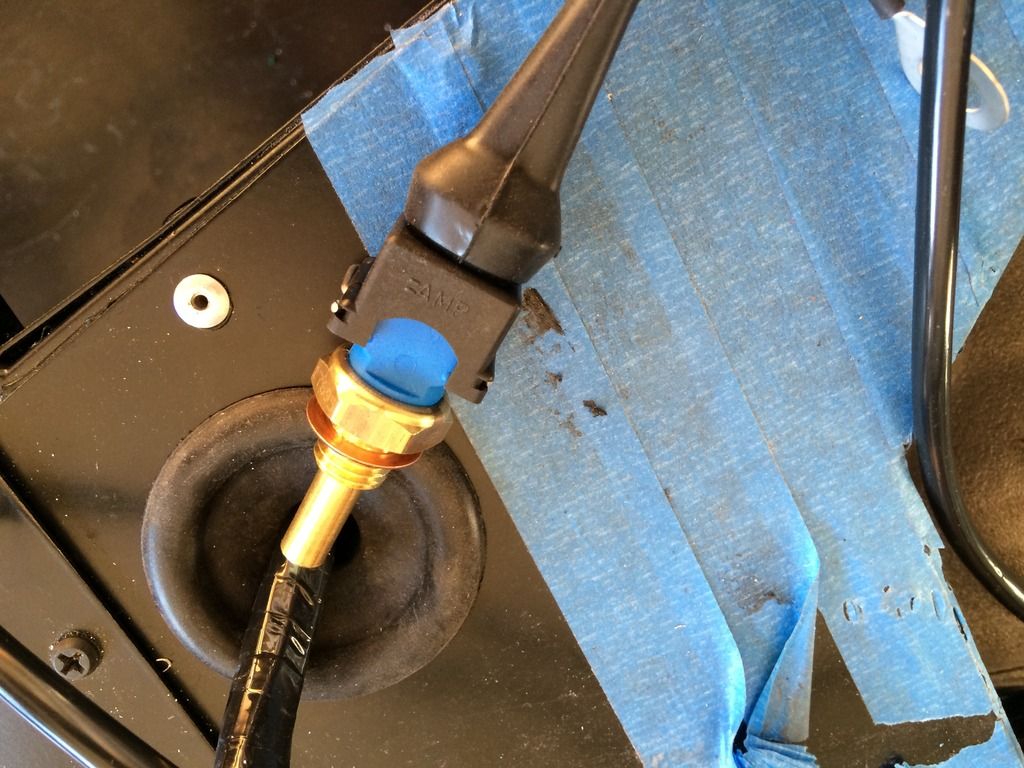

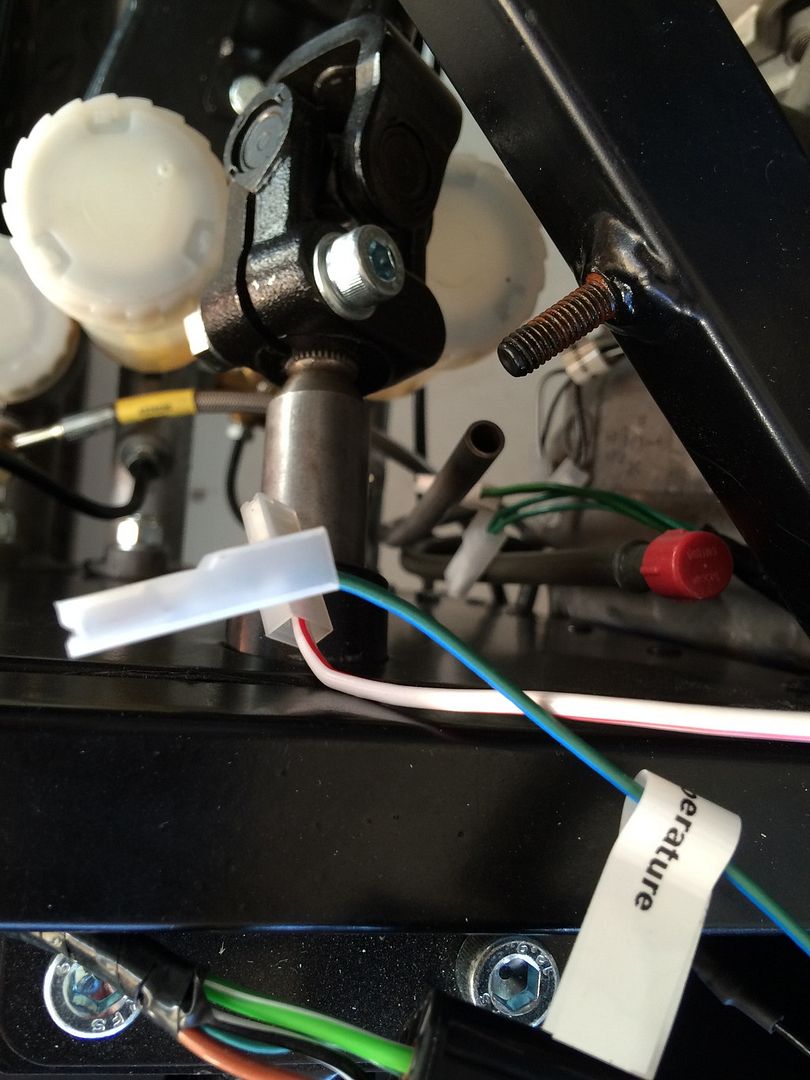

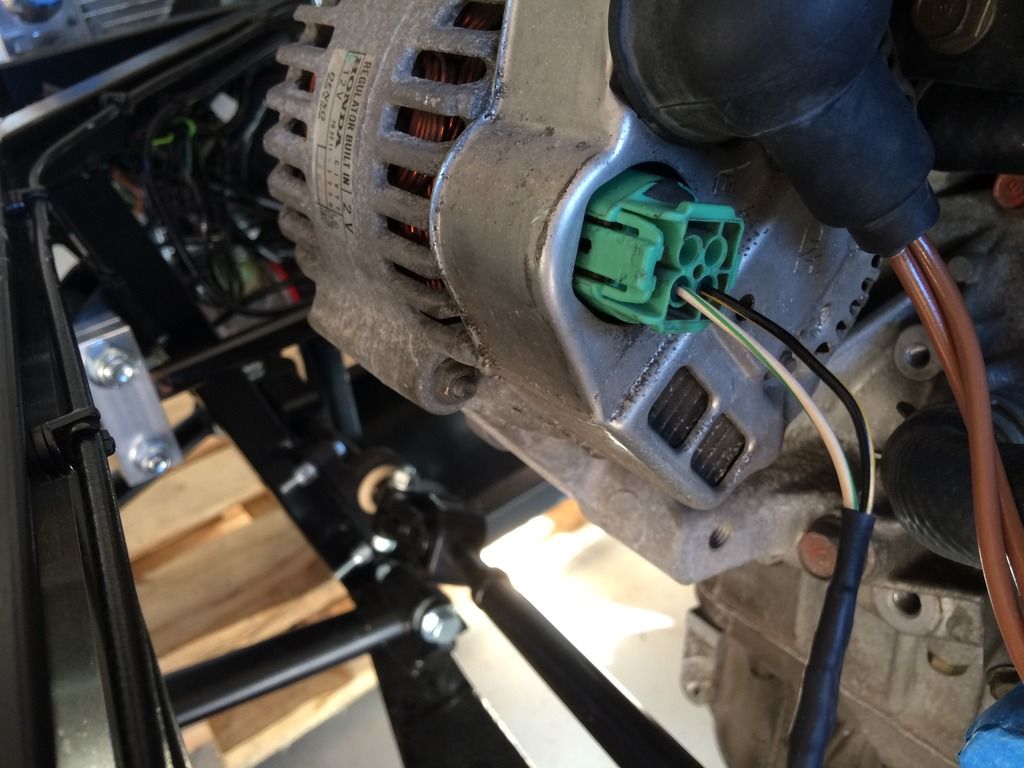

I was also able to load the configuration file for the digital dash and am getting readings, but I am not sure I believe the oil pressure - it is showing 0.5 (bar?) on idle and 2.5 at 3,000 rpm. Compression on all cylinders is good, so would not expect low oil pressure. The readings should be somewhere around 2.5 bar at idle and a lot more than that at higher revs, I believe, so that is a question for Westfield - is the equation in the configuration file wrong, is the sender working properly or do I have an engine problem? I am fairly sure about it not being the third option based on the aforementioned compression test and the fact that there is no blue smoke on fire-up.

Thought I would also check at what indicated temperature the fan came on, so I let it idle to warm up - by the time the temperature was reading 100C, the fan still hadn't cut in so I shut it down and checked the connections - I could hear the relay switching on and off, but no fan - turned out the fuse was a dud, so replaced it and the fan came on at and indicated 80C and off at 76C, This is low - the fan should come on somewhere around 96C, so is it the calibration of the dash, the sender unit for the temperature or the sensor for the fan. Another question for Westfield. The dash also says I have 18 fuels. I wonder if that is 18% - that may make sense as I only put a couple of gallons in the tank.

I want to convert everything to American readings (F and psi), which is easy to do with a laptop plugged into the dash, but first I want to be sure everything is reading as it should. I also have to configure the speedo settings for the specific wheels/tyres, which is relatively straightforward, but I need direction on how to wire in the speed sensor, which isn't part of the wiring harness. Another question for Westfield.

Also got a confirmation today from Tom and Manik that they are sending me a set of competition tyres as originally ordered, and it seems they don't want the others back - will be useful for setting up the car on the road, as I don't think the competition tyres are actually street legal.

Finally, had a visit from Son of Sid on Saturday morning - a small snake that got into the courtyard. It seemed harmless enough so I left it well alone after spending 20 minutes or so playing hide and seek behind the hose reel (the snake was hiding behind the reel, not me). The on Sunday we had another visitor, indoors:

|

| Say goodbye, Mr Scorpion |

However, unlike snakes, scorpions are not protected in the State of Arizona, so this little chap was dispatched to meet his maker with a swift thwack of my shoe. Just as well, as they pack a nasty sting in that tail.