It's been a while - have been road testing and sorting out the finishing touches. Temperatures have been 110+ F here and am still getting some engine pinging - have tried octane boost, but am not a fan after reading up about the stuff on the internet - at least I don't have to worry about it damaging the cat! I did find 95 octane (US system) racing fuel at a gas station near me, at $6 a (US) gallon, it seems a bit steep when you can by a whole barrel of oil for under $40! It has, however, solved the ping issue, mostly.

Took the car to have the graphics done. While I am waiting for the replacement bonnet and boot lid, I decided to have the damaged ones wrapped in carbon fibre to hide the cracks - it does a really good job of concealing the damage. They did a great job! A dark pinstripe around the rear wheel arch join hides the poor fit. Getting the stripe right at the rear was a challenge, given the droopy right side of the rear panel and the fact that the car doesn't sit level without me in it!

|

| My first view of the transformed Mr. Westfield |

|

| Detail of the carbon wrap - really good job |

|

| Anyone for Gulf? |

|

| lovely rear view. Lots of other drivers will be seeing this |

|

| Hopefully people will stop asking what is under the bonnet! |

An Audi RS7 driver discovered how quick Mr. Westfield is on the way home from the graphics shop. He thought he beat me away from the lights, but he sounded like he was at WOT and I was only at 4,000 RPM - I took it easy as I was worried about the trunklid flying off - I had taken the locks off to get it wrapped! Quattro and electronics did help getting the power down for the Audi - quite a challenge in Mr. Westfield

Fitting the side impact bars has been a pain in the rear, and not something I would recommend for the faint of heart. The supplied bars do not fit the Honda chassis, because of the dropped floor. Westfield told me it was as straightforward as extending the upright piece that wraps under the floor and mounts to the underside using the seat mounting bolts.

If only it was that easy.

So the plan was for me to cut the tubing and temporarily add an extension so that everything fit, then get a fabricator to insert an appropriately size piece of tubing, with a pipe on the inside for strength and then weld everything up. What they finally decided to do for security was to replace the whole upright piece, which required making a jig.

I say this is not for the faint-hearted for several reasons:

- it requires cutting large holes out of the rear of the bodywork

- you have to drill holes in the bodywork for the front mounts

- you have to cut your expensive, new powder-coated impact bars

- You have to weld next to your nice new fiberglass bodywork

I would not recommend anyone buying these until Westfield fix them so they do fit. They did have a good point in that they were only originally intended for the race car. Apparently, I am the first to try to fit them to a chassis with the lowered floor. Ian in the parts department did say (after they sent them) that he wondered why I had ordered them, because they knew they wouldn't fit! It would have been useful for them to tell me that before they sent them.

With their insistence that the only modification was to extend them to account for the lowered floor, I went ahead and made the required cuts to the bodywork. No going back after that. You have to cut the bodywork in order to see if they fit, as the mounting plate is much larger than the one for the roll bar.

You can see it marked out approximately here:

|

| Do I really want to cut this? |

The trouble is, once you have cut this much out, there is nothing left holding the front lip of the rear panel to the sides (lower left in the picture). Cutting this close to the edge also chipped the gelcoat. Once the side bars are in, the half cage sits on top of them.

The front mount is located by drilling through the crush tube in the chassis from the inside.

|

| Perfectly drilled hole, but . . . |

Nice and neat. Definitely no going back.

Next step is to cut the upright on the impact bar just below the T, so I can fit each piece and see how much needs to be added.

This is where the fun started.

When I mounted the top plate, the front mounting point in the chassis didn't line up:

|

| . . . Bugger it! |

Not even close. I can't move the top mount forward, as this would move the half cage forward, and the rear body holes are already cut.

Mounting up the bottom portion showed that the mounting holes were in the wrong place - they were about an inch off so I drilled new holes in the bottom plate to move the plate inwards so the two pieces of tubing would line up approximately (the bar was also fouling on the exhaust) - They also wouldn't line up from front to back.

|

| Touches the exhaust |

|

| Seems a little out of alignment |

|

| And out this way too |

The solution was to cut off the bottom mounting plate, tack in the required extension piece, then retack to the bottom mounting plate. Lots of worry about setting fire to the car! I was so worried about the fiberglass that I forgot about the exhaust and got some spatter on the rear pipe - hopefully it won't cause a problem with rust down the line.

Not the best of welding jobs, but it was fine to mock up the piece. The driver's side was an even worse fit, with the front mounting point way off and at an angle (shown prior to drilling the hole):

|

| Beautifully bodged extension form a piece of home depot plumbing pipe |

|

| That's not right |

I worked with the fabricator at his shop to do the final fit and adjustments. As I mentioned above, they made an entirely new upright piece. I am much happier about this approach than patching in an extension. They also said the tubing used for the supplied bars was quite thin - the new upright is much thicker and will be the only piece left standing if ever there is an impact!

The solution to getting everything to line up with the front mounts? Cut off the rear mounting plate (and the bottom mounting plate, again - fortunately it had only been tacked in) add an extension to the vertical part of the mounting plate where the bar attaches and remount it. It would have been easier to build the bars from scratch.

|

| OK now, lets weld right next to the fuel tank vent pipe . . |

Here we see Mr. Westfield wearing his protective aprons. I was a little worried as the gas tank vent was right under there and the tank was full of 95 octane race fuel! Fortunately, we didn't blow him up. You can see where the bar was cut off. We had to move it forward a good 15-20mm on the driver's side. The front mount will be bevelled to align better with the body.

Everything should fit nicely once it comes back from being welded up and powder coated. What a faff, but well worth it - hopefully I will never need to test them out. My feeling is the bolts on the seat mounts are a little small to hold this securely, so I will probably replace them with some thicker ones. Unfortunately I had welded them in, so it will need some careful surgery at some point.

The bars should be ready next week and I will be able to get everything back together.

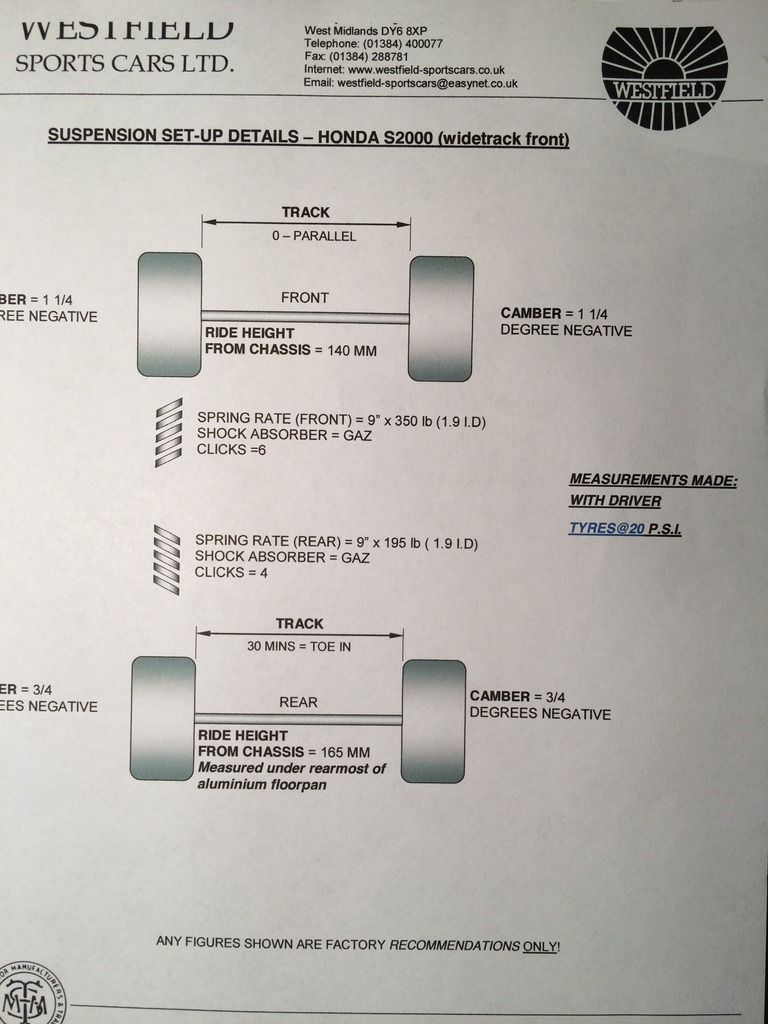

I have to finish setting up the suspension geometry (front done - except that Westfield say I have to change the upper ball joint washers for some thicker ones , but the rear is a little more involved), and then I am taking it down to the track on the 15th for testing. Can't wait! Alex will be flying in form Montreal to help - however, it looks like I need to move the driver's seat back to accommodate his legs, based on his brother's trial over the weekend - his knees were touching the steering wheel, which now has a removable hub (and is a better wheel)